DESIGN HINT: Not All Fiber Cement is Created Equal!

For rainscreen cladding applications, not all fiber cement panels are created equally. Cladding Corp is pleased to offer Swisspearl® products that are air-cured, a process where cement-based products cure naturally, with a 28-day curing process, that saves energy and reduces internal panel stress.

An air-cured fiber cement product is always superior to an autoclaved product, as the panels are dried naturally over time, allowing for natural chemical bonding of the fibers and taking out the added heat energy and internal panel stress.

To assist the design community, Swisspearl® and Cladding Corp have developed a comparison of the characteristics of Air-cured Fiber Cement versus Autoclaved Fiber Cement. Ingredients and heating create very different crystal structures, resulting in products that are not the same. We hope the discussion will provide additional insight for designers who are committed to sustainability manufactured, high-performance fiber cement cladding panels designed for large-scale, long-term construction.

How are fiber cement panels created?

Fiber cement consists of the following organic components, by volume ratios, after oven curing or a hardening period of 28 days. Exact formulas are proprietary by the manufacturer, but in general, ratios are as follows:

- 72% cement

- 15% water

- 6% air

- 5% pulp

- 2% recyclable plastic fit

How are the raw panels dried?

- Panels are stacked in sheets and then rest in a climate-controlled area for up to 28 days so the concrete can cure.

- They are dried in a way similar to a dehumidifier, making them less porous.

- After 3 weeks of setting, the water content reduces to 7 to 8%, and the panels are ready for further processing.

- The panels are not baked, pressurized, or burned; the natural air is controlled. Other manufacturers autoclave their fiber cement panels, which are steam hardened in ovens.

- Depending on the coating, certain panels will also go thru a hydrophilization process.

A Comparison: Air Cured vs Autoclaved

| Air-cured | Autoclaved | |

| Definition | A process where cement-based products cure naturally 28-day curing process |

A process where the cure time of a cement-based product is rapidly accelerated through the use of a high-temperature 24-hour curing process |

| Ingredients |

High-quality raw materials create a better finish. More cement and PVA fibers used |

More filler and chemical bonding materials needed for the rapid heating process. A sanding process is used to remove panel imperfections |

| Creep Capacity |

Increased “Creep”. High creep capability reduces tensile stresses from normal expansion and contraction. Less stress on fixing points and longer-lasting durability |

Accelerated curing from heat causes panels to be brittle. Expansion and contraction of non-engineered substructure can cause panels to crack |

| Energy for Curing |

Accelerated curing from heat causes panels to be brittle. Expansion and contraction of non-engineered substructure can cause panels to crack |

High energy use to rapidly cure panels. Increases carbon footprint |

| Panel Stress for Curing | Dries naturally without stress and natural chemical bonding. PVA fibers are excellent at adhering to cement |

Accelerating the curing process using added temperature can cause induced stresses within the panel for a variety of reasons |

| Moisture Movement in Panel |

Low moisture movement in the panel. Reduces internal panel stress |

Higher posture movement {caused by additives} affect “carbonation,” which creates internal stresses in the panel |

| Chemical Attacks from the Environment | Better resistance to chemical attacks in the environment |

The crystal structure is more susceptible to discoloration from atmospheric CO2 |

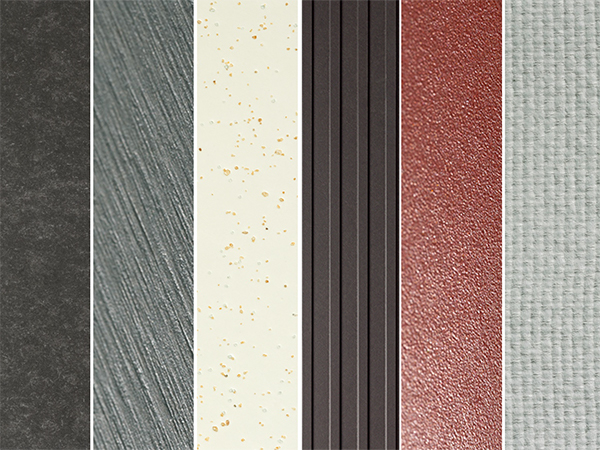

Swisspearl® is the industry leader in the High-Density Fiber Cement Category offering the highest quality ingredients, production quality control, finishes, and standards.

Swisspearl® panels are Air-cured, contain PVA fibers, Stable colors, and 72% Portland cement as the bonding agent. This ingredient, sintered from limestone and marl clay, is proportionally the most important base material. The bonding of the lime with the silicic acid contained in the marl gives the fiber cement its outstanding compressive strength. Synthetic and organic polyvinyl alcohol fibers (PVA) are used as reinforcements for binding. Swisspearl High-Density Fiber Cement is engineered for durability, absorption, and high performance.

For additional technical information on the high-performance fiber cement rainscreen solution available through Swisspearl and Cladding Corp, contact us.